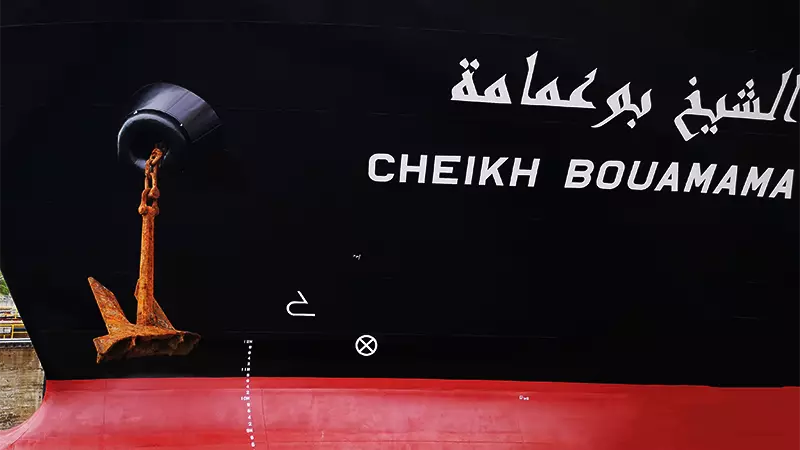

On 1st of July 2021, Cheikh Bouamama, Spain, we successfully completed the drydock job.

On 1st of July 2021, Cheikh Bouamama, Spain, we successfully completed the drydock job.

The vessel was coming to Ferrol for their 5 yearly drydock inspection. They needed qualified engineers to overhaul 10 Nakakita steam valves for the Steam Turbine main engine along with a general check on the tank level gauge system.

All the valves were disassembled. Once disassembled the cage & piston were examined for wear and replaced where necessary. Gaskets and o-rings replaced and seats were lapped. Once the valves were re-assembled back into position, all the pneumatic and electric positioners were checked and calibrated. Once this was complete dit was found that the temperature controllers were out of sync. A few hours later and everything was functioning correctly. During commissioning all valves were inspected and tested by the class surveyor and found to be in full working order.

Get in touch with us

For the tank level system we had been warned that this was not functioning correctly. After some investigation and troubleshooting on the system we found that the zenner barrier of 4 of the water ballast tanks were defective. Having replaced these it was then a matter of going to each tank and testing and calibrating each sensor with a hand pump.

Once everything was completed, one engineer went on the sea trials to ensure that all work was carried out to the satisfaction of the owners and Class surveyor before returning home.

This is just one of many jobs on board that Ravebo Marine Services can carry out. Being the officially authorized service partners of Nakakita, Georim, KangRim and Tanktech, Ravebo engineers can carry out the service of many different types of equipment on board.