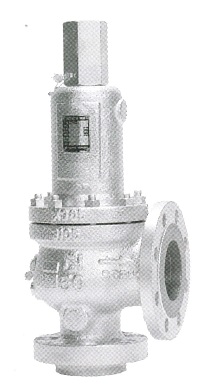

With concentrated efforts, by constantly developing new techniques, furthering quality assurance of improved products and making it our motto to produce safety valves which guarantee full satisfaction of every customer, Nakakita vigorously has been striving toward safety of various plant facilities. As an authorized manufacturer to use the ASME Code stamp, together with its acquisition of international standard (IS0 9001) Nakakita's quality control system has been highly recognized worldwide and Rence resulting in great amount of delivery. NS 255 F Series full bore safety valve is a steam use safety valve for boiler, pressure vessel and any other pipeline, widely installed in all industries. This series of valves have been created by Nakakita's special engineering under their ever-lasting technical innovation and their plentiful engineering experience, and its performance superiority has been confirmed through every severe and detailed test.

With concentrated efforts, by constantly developing new techniques, furthering quality assurance of improved products and making it our motto to produce safety valves which guarantee full satisfaction of every customer, Nakakita vigorously has been striving toward safety of various plant facilities. As an authorized manufacturer to use the ASME Code stamp, together with its acquisition of international standard (IS0 9001) Nakakita's quality control system has been highly recognized worldwide and Rence resulting in great amount of delivery. NS 255 F Series full bore safety valve is a steam use safety valve for boiler, pressure vessel and any other pipeline, widely installed in all industries. This series of valves have been created by Nakakita's special engineering under their ever-lasting technical innovation and their plentiful engineering experience, and its performance superiority has been confirmed through every severe and detailed test.

Function

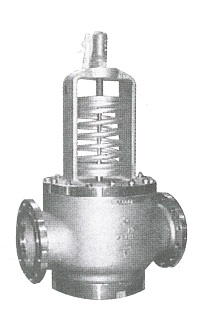

NS 255F Series full bore safety valve is a popping type safety valve which has an open bonnet and lifts up instantly by more than a quarter of the throat bore. The safety valve of this series is equipped with unique valve disc structure and adjusting mechanism to secure positive tightness and smooth operation. These arrangements enhance the safety function and secure the performance required.

Standard disc

The flexible structure is a standard feature of the disc of Nakakita safety valves, as shown in the figures below. This flexible structure isolates the valve disc from undesirable effects of thermal deformation of the valve body. In other words, as the valve disc and the holder are not rigidly connected with each other, the seating surfaces of the disc and nozzle are kept prallel with each other irrespective of thermal deformation during actual service and positively prevent leakage.

Get in touch with us

Super disc

This disc is effective when strict tightness is required under severe service conditions which cannot be adequately covered by the standard disc. This disc is equipped, in addition to above-mentioned structural flexibility, with a specially formed lip which has powerful self seating function, as shown in the figure below. This lip is made of special alloy having appropriate hardness and elasticity. Even when the fluid pressure reaches near to the set pressure, seat clamping force can be maintained by the pressure of the ring-shaped space between the lower face of the disc and the lip, and by the elasticity of the lip itself. Leakage prevention is positively affected just prior to popping.

This disc is effective when strict tightness is required under severe service conditions which cannot be adequately covered by the standard disc. This disc is equipped, in addition to above-mentioned structural flexibility, with a specially formed lip which has powerful self seating function, as shown in the figure below. This lip is made of special alloy having appropriate hardness and elasticity. Even when the fluid pressure reaches near to the set pressure, seat clamping force can be maintained by the pressure of the ring-shaped space between the lower face of the disc and the lip, and by the elasticity of the lip itself. Leakage prevention is positively affected just prior to popping.

Adjusting mechanism

Two adjusting rings and a back pressure adjusting cock are devised as adjusting mechanism, and their respective works are as follows:

- Lower adjusting ring; to form a popping groove in the part and make a popping action.

- Upper adjusting ring; after popping, to raise the disc up to the rated lift and maintain it there. The ring is also used for adjusting the closing pressure.

- Back pressure adjusting cock; a very important part which adjusts the back pressure of the exhaust chamber above the disc, so as to prevent chattering, fluttering, etc. which come with the rapid pressure drop after discharge. The cock also adjusts the closing pressure.

Precise Operation

NS 255F Series full bore safety valve designed in every detail by the most updated valve manufacturing techniques and well established engineering, remarkably displays its most vital function of opening and closing.

Assured Capacity

As it is a nozzle type full bore safety valve, discharging capacity of NS 255F Series is the largest of the same size safety valves of various types and promised economical efficiency as well. Approval by The National Board and such various Classification Society as NK, LR, NV, BV, CR, KR, etc as wel1 as JG (Marine Department of Ministry of Land, Infrastructure and Transportation) guarantees complete reliability of valve's performance.

As it is a nozzle type full bore safety valve, discharging capacity of NS 255F Series is the largest of the same size safety valves of various types and promised economical efficiency as well. Approval by The National Board and such various Classification Society as NK, LR, NV, BV, CR, KR, etc as wel1 as JG (Marine Department of Ministry of Land, Infrastructure and Transportation) guarantees complete reliability of valve's performance.

Positive thightness

NS 255F Series full bore safety valve completely resolves leakage problem as it is designed to prevent thermal distortion through due consideration on material, shape and structure of disc and nozzle, and by the special seating surface finished by Nakakita's unique lapping scheme.

High maintenance

NS 255F Series full bore safety valve is able to constantly maintain its initia1 conditions through easy lapping when necessary as disc and nozzle fully flat finished. Another easy maintenance with interchangeable components worked by NC machines.

Excellent quality

NS 255F Series full bore safety valve is manufactured by well established valve design technique, production engineering and a rigorous quality control system, hence resulting in great amount of delivery.