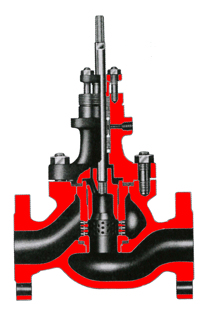

Control valve with cavi-cage

This control valve is equipped with trim-exchangeable multiport cage. It is used to prevent erosion of the body and trim. In boiler feed water control valves, etc., the pressure drop at start-up or during low load running may become excessive and come into the range of cavitation generation. It reduces the service life of the body and trim and causes maintenance problems. The cavi-cage has such construction that the fluid jets into the cage towards its centre through small holes in the circumference of the cage. At the throttle of each small hole, the static pressure decreases due to high velocity of the fluid, and the resulting choked flow generates bubbles which cause cavitation. These jets are arranged to collide with each other directly in the centre of the channel to dissipate cavitation energy. Erosion of the body and trim is thus prevented by arranging small holes opposing with each other in the circumference of the cage to suit the flow characteristics.

This control valve is equipped with trim-exchangeable multiport cage. It is used to prevent erosion of the body and trim. In boiler feed water control valves, etc., the pressure drop at start-up or during low load running may become excessive and come into the range of cavitation generation. It reduces the service life of the body and trim and causes maintenance problems. The cavi-cage has such construction that the fluid jets into the cage towards its centre through small holes in the circumference of the cage. At the throttle of each small hole, the static pressure decreases due to high velocity of the fluid, and the resulting choked flow generates bubbles which cause cavitation. These jets are arranged to collide with each other directly in the centre of the channel to dissipate cavitation energy. Erosion of the body and trim is thus prevented by arranging small holes opposing with each other in the circumference of the cage to suit the flow characteristics.

Get in touch with us

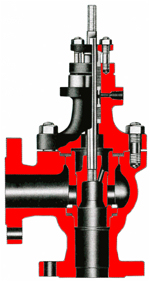

Cage type double seated angle control valve

This control valve is DY-C control valve of which body type (globe type) is replaced with the angle type. Both cage trim and actuator are common to the DY-C type, and this control valve has wider advantages such as low maintenance and high controllability. It is possible to fit cavi-cage or low noise trim on this valve. The installation of the protective liner which is a seat ring elongated to the downstream side prevents erosion of the inner wall of the body due to cavitation and flashing.

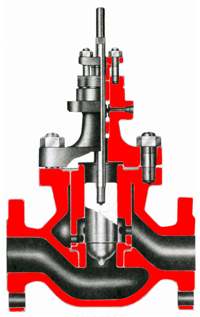

Cage type single seated control valve

This control valve is a single seated valve using a cage port. It is used when low leakage is required. As it is a single seated valve, a large force is required to close the valve. Accordingly, its use is normally confined to small pressure drop services. However, when pressure drop is large, a high output diaphragm type or cylinder type actuator is used. It is possible to meet non-leakage requirements by using soft a sealing material on the seat of this valve.

Cage type double seated control valve

The main feature of this control valve is the simple construction which allows an easy trim exchange in a short time without disconnecting the body from the piping during maintenance. The cage has flow characteristic ports in its circumference. The plug guided by the cage has balance holes. With this arrangement, unbalanced forces are offset and the dynamic unbalanced force on the stem is stable over the whole range of the valve travel. This in turn reduces the load on the actuator to secure stable controllability. As this control valve is a balancing type double seated one, it is possible to limit the leakage at full closure within 0.3%, from low temperature range up to high temperature range, by adopting materials of small thermal expansion difference for cage and valve plug. Bodies are available in two types for most of the sizes and pressure ratings; S-series body (S: standard), and E-series body (E: enlarged).

Low noise control valve

This control valve exhibits effective noise reduction by means of multi-stage pressure reduction and dispersion of the flow and frictional resistance into many small hole throttles. It has a unique construction developed by NAKAKITA. The flow of the liquid enters the plug, from the lower side of the body, through the control port consisting of many small holes in the lower portion of the cage. The flow then goes through the control port consisting of small holes in the central portion of the plug and enters the recess at the centre of the cage, and the flow velocity is reduced. This flow then runs out to the downstream side of the body, through the small holes of fixed resistance in the outer circumference of the cage, in dispersed small streams. In this way, pressure reduction and flow dispersion are repeated through three stages consisting of two-tier control ports and fixed orifice, so as to reduce the noise.

Unbalanced single seated control valve with cage guided plug

This control valve is an unbalanced single seated valve with rigid trim construction where P-port heavy guide plug is guided by the cage. As for its actuator, a powerful high output diaphragm type or cylinder type is used. The stored cage receives the jet out of the throttle and releases the flow through small holes in the circumference of the cage to the body side. It thus protects the inner wall of the body from erosion due to the jet of the fluid. This valve is used for large pressure drop service which generates flashing, cavitation, etc. One of the main applications is the emergency drain escape valve of high pressure feed water heater.

This control valve is an unbalanced single seated valve with rigid trim construction where P-port heavy guide plug is guided by the cage. As for its actuator, a powerful high output diaphragm type or cylinder type is used. The stored cage receives the jet out of the throttle and releases the flow through small holes in the circumference of the cage to the body side. It thus protects the inner wall of the body from erosion due to the jet of the fluid. This valve is used for large pressure drop service which generates flashing, cavitation, etc. One of the main applications is the emergency drain escape valve of high pressure feed water heater.