This controller can be applied to all possible detection fields of process control such as pressure, differential pressure, temperature, liquid level, flow rate, viscosity etc. when used in combination with diaphragm control valves at the operating end. It is a pneumatic controller which can automatically regulate various process conditions at the optimum level.

This controller can be applied to all possible detection fields of process control such as pressure, differential pressure, temperature, liquid level, flow rate, viscosity etc. when used in combination with diaphragm control valves at the operating end. It is a pneumatic controller which can automatically regulate various process conditions at the optimum level.

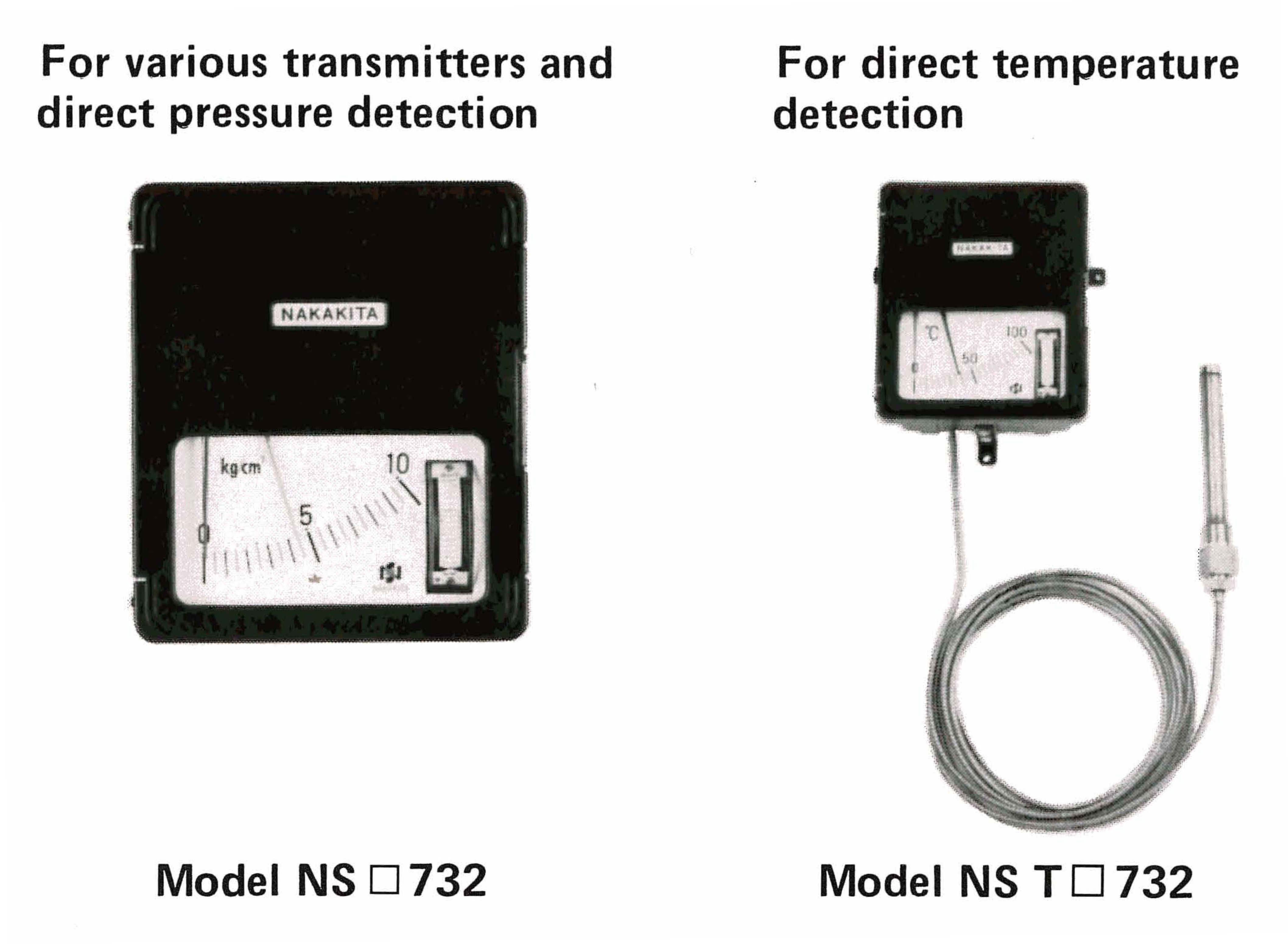

It is constructed compactly and weights light, incorporating least possible number of parts. Its control, handling and maintenance are therefore simple and yet it has considerable durability. It is an instrument most suitable not only for fixing on graphic panel but also for local control, having usages in versatile fields.

Specifications

- Control air pressure(output): 0.2 - 1.0 kgf/cm

- Supply air press : 1.4 kgf/cm

- Control operation

- Proportional band: 10 m 250%

- Reset time: 0.2- 0.1 - 20 min (Standard), 2 - 40 sec, 0.5 m 10 sec

- Rate time: 0.05-10 min control valve

- Both direct and reverse actions are available

- Accuracy: Within 1% of full scale

- Method of fixing: Panel mount or wall mount type

- Casing: Drip-proof and dust-proof type

- Weight: ca. 5 kg. (When detecting element is TM, TG, ca. 6 kg)

- Air consumption: Normal : 1 Nl/min, Maximum : 30 Nl/min

- Connection for control and supply air: PT1/4

- Pressure measuring connection: PT1/4

Get in touch with us

| Controlled system | Detecting element | Standard measurement range | |

| Configuration | Material | ||

| General | Bellows unit used only for pneumatic pressure signals of 0.2 to 1.0 kgf/cm2 |

phosphor bronze | to be suited to the transmitter |

| Pressure | Direct pressure type bellows unit | phosphor bronze | 0-0.5, 1, 2, -0.1 / 0.2, 0.4 kgf/cm2 -0.2,/ 0.8, -0.5 / 0.5 kgf/cm2 |

| Direct pressure type spiral Bourdon tube unit | AISI316-brass complete AISI316 |

0-3, 5, 10, 15, 20, 30, 50, 100 kgf/cm2 |

|

| Temperature | Direct temperature type mercury expansion type thermal unit and gas-filled thermal unit |

AISI304 | 0-100, 150, 200, 300, 500 °C |

| Level | Displacement type level detecting element | 250-2000 mm (to suited to the detecting element) | |