Ravebo Marine Services recently carried out a technical maintenance and troubleshooting job onboard an oil carrier anchored off Turkey. During this service, several critical systems were inspected, tested, and restored including the AUS, ADS, and COPT systems.

Work Performed

Our experienced service engineers completed the following:

AUS system

The Automatic Ullage System (AUS) was thoroughly inspected to identify the cause of operational inconsistencies. Our engineers checked the condition and calibration of the pressure transmitters, verified the performance of the vacuum pumps, and evaluated the valve actuation logic. Once the faulty components were identified and adjusted, the system was successfully restored to full automatic mode. Additionally, the vessel’s crew received on-site instruction to ensure proper handling and monitoring of the AUS system moving forward.

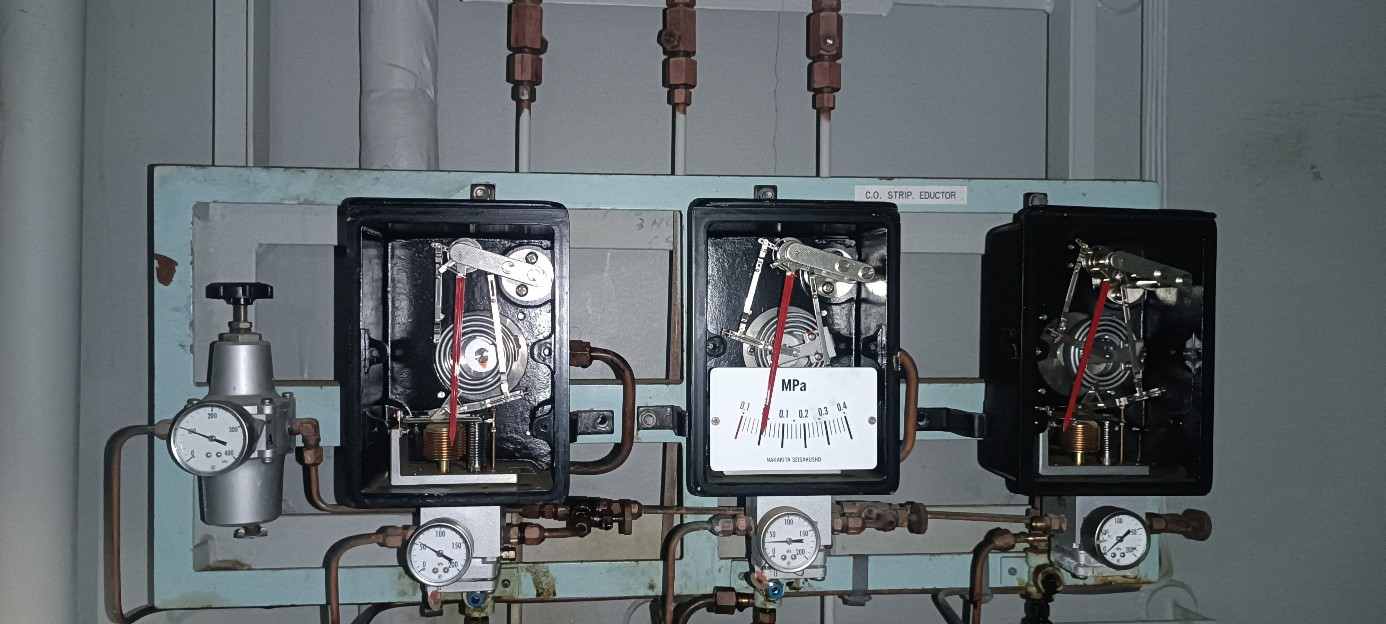

ADS system

An issue within the Automatic Discharge System (ADS) was traced to an air leak in a relay, which was interfering with signal transmission and valve responsiveness. The faulty relay was carefully isolated, and the leak was eliminated. Following this, the control loop signal was verified and recalibrated, and the valve positioner was reconnected and fine-tuned to restore smooth and accurate operation. The system was tested under live conditions to confirm proper functionality.

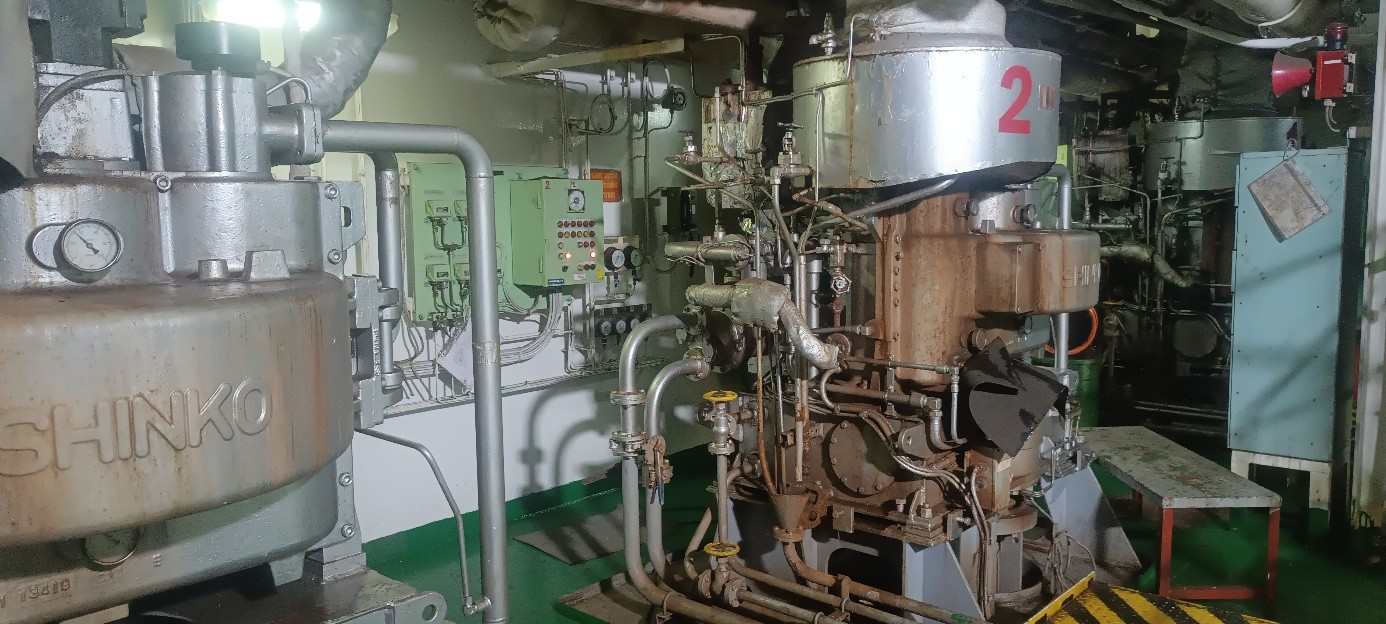

COPT system

The Crude Oil Pump Turbine (COPT) system underwent a full inspection. Remote operation was initially unresponsive, our team identified several faulty components affecting signal communication. Manual operation was used to verify functional parameters and to keep the system operational while replacement parts are sourced. Recommendations for long-term solutions were provided to the vessel operator.

Pressure transmitters and level controller

All pressure transmitters and level controller within the pump room were inspected and calibrated according to standard maritime guidelines. Any units displaying drift or signal irregularities were removed and replaced with calibrated spares. Full calibration certificates were issued for all active and healthy units. These records are now part of the vessel's technical documentation, ensuring traceability and compliance with regulatory standards.

Recommendations

To ensure optimal performance and system reliability, we advise:

- Cleaning sensing lines to improve measurement accuracy

- Replacing defective transmitters and relays

- Scheduling regular functional tests of AUS, ADS, and other automation systems

- Implementing a fixed calibration schedule and logging system for all pressure and level transmitters

Global Service, Local Impact

This job once again demonstrates Ravebo’s commitment to delivering high-quality maritime service worldwide. Whether it’s maintenance, troubleshooting, or installation we make sure your systems keep running