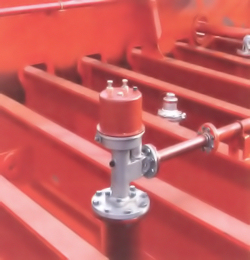

Non-programmable Twin Nozzle Tank Cleaning Machine

NPM-40 and NPM-50 can be used on all kind of chemical tanker as well as crude oil tanker. In order to select the specification of Tank Cleaning Machine, pump capacity, machine quantity operated simultaneously, related standard, the kind of cargo, etc, and are required with general information of cargo tank such as dimension and shape. TANKTECH can provide crude oil washing manual and shadow diagram.

NPM-40 and NPM-50 can be used on all kind of chemical tanker as well as crude oil tanker. In order to select the specification of Tank Cleaning Machine, pump capacity, machine quantity operated simultaneously, related standard, the kind of cargo, etc, and are required with general information of cargo tank such as dimension and shape. TANKTECH can provide crude oil washing manual and shadow diagram.

Operation

The body of NPM Series is rotated around the vertical axis by cleaning fluid. At the same time, the cleaning fluid spins the nozzles around the horizontal axis. As a result, the grid pattern traces are generated on the walk of tank. The tank cleaning operation by NPM Series consists of cycle patterns as followed figures. The whole part of cargo tank is covered by these 4 cycles.

Get in touch with us

Programmable Single Nozzle Tank Cleaning Machine

CLEANMAX UPM-4050 and UPM-6580 are completely a programmable single nozzle Tank. Cleaning Machines to be equipped on the mounted tank top or deck. It will allow adapting in crude oil and product/chemical tankers as wel1 as industrial applications. TANKTECH can provide the COW (Crude Oil Washing) manual and the shadow diagram to be thoroughly complied with the latest IMO Assembly Resolution A.897 (21). Optimized single nozzle unit of CLEANMAX wil1 give much more advantages compared with twin nozzle unit deliberating on the savings in pumping, stripping and piping and longer effective jet length.

CLEANMAX UPM-4050 and UPM-6580 are completely a programmable single nozzle Tank. Cleaning Machines to be equipped on the mounted tank top or deck. It will allow adapting in crude oil and product/chemical tankers as wel1 as industrial applications. TANKTECH can provide the COW (Crude Oil Washing) manual and the shadow diagram to be thoroughly complied with the latest IMO Assembly Resolution A.897 (21). Optimized single nozzle unit of CLEANMAX wil1 give much more advantages compared with twin nozzle unit deliberating on the savings in pumping, stripping and piping and longer effective jet length.

Operation

CLEANMAX UPM series is the fluid-driven machines and their spiral motion for the single nozzle fully managed by the integrated turbine driven control unit. It can set up to control a vertical pitch of nozzle as like 1" and 3" so that it is able to adjust the cleaning time and cleaning frequency, injection density during washing operation. It is possible to vary the cleaning time by setting the speed adjustment knob under the same flow rate. Most of all, it is possible to set up any required washing range within -25" to 155" during single or multi-stage operations.

Advantages

- Easy operation setting & al1 visible indication

- Compact design

- Alt setting can be adjusted during washing without stopping of cleaning agent supply.

- Infinite repeating cycle without stop of washing operation after setting of operation range

- No further requirement after setting of any required range

- Easy maintenance & inspection

- Operation of the machine is monitored by attaching the sensor, and the signa1 is transferred to AMS;

- Single or multi stage operation at any desired angle range