A Marine incinerator is a machine on board that burns all types of waste generated on the vessel. This includes waste oil from the separator, rags, galley waste and in special incinerators plastic as well. This was regulated by IMO MARPOL 73/78 resolution MEPC.176(40), adopted 10th October, 2008 and IMO MARPOL Annex VI, Chapter III Regulation 16. All (new) incinerators installed onboard a ship on or after 1st January 2000, require compliance with the above regulation and must have an IMO type approved certificate.

A Marine incinerator is a machine on board that burns all types of waste generated on the vessel. This includes waste oil from the separator, rags, galley waste and in special incinerators plastic as well. This was regulated by IMO MARPOL 73/78 resolution MEPC.176(40), adopted 10th October, 2008 and IMO MARPOL Annex VI, Chapter III Regulation 16. All (new) incinerators installed onboard a ship on or after 1st January 2000, require compliance with the above regulation and must have an IMO type approved certificate.

Disposing waste

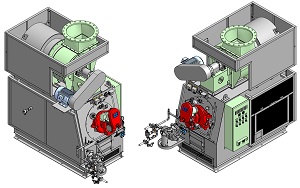

It’s an important and critical piece of equipment on board a vessel in order to dispose of the waste generated in an easy manner instead of storing it on board or disposing of it overboard that in itself is creating a vast amount of pollution. The flue gasses of a furnace can be used for heating water. But for that purpose the incinerator needs to be operated for a lengthy amount of time. Sunflame is producing incinerators with a combustion capacity from 190KW to 1500KW, and all are equipped with a Rotary Cup Burner.

Get in touch with us

Eco-Friendly Waste Management with Incinerators

Incinerators are the ultimate solution for waste treatment onboard vessels, offshore units and onshore facilities. Models cover capacities from 190.000 kcal/h to 1.290.000 kcal/h. Incineration of liquid and solid waste is considered to be an environmental friendly way of waste management. Onboard incineration with local management of sludge oil and solid waste is highly appreciated, and recommended by the International Marine Organisation (IMO) and all the class societies. Most Incinerators are computerized (PLC) to make the daily use simple, automated and safe for the user over a long product life, and always ensuring compliance with the IMO regulations.

Onshore

Incinerators are also perfect for waste treatment at onshore facilities, especially in remote areas. Incinerators are used in power plants, mines, hotel resorts and military units all over the world. All incinerators are running at a high temperature to enable high capacity for burning both liquid and solid waste, and in spite of this, have relatively small dimensions.

What can be incinerated?

According to the IMO regulations the following solid and liquid waste can be burned in an IMO certified shipboard incinerator:

- Plastic, cardboard, wood

- Rubber, cloth, oily rags, lub oil filters

- Diesel engine scavenge scraping

- Paint scraping

- Food waste, etc.

- Sludge oil, waste lubrication oil

- Hospital waste, female hygienic binds

- Destruction of contaminated water

Materials

Material, which contains more than traces of heavy metal and of refined petroleum products containing halogen compounds, is prohibited to be incinerated. Light bulbs contain heavy metal and thus, are prohibited to incinerate. Under shipboard operational waste the following materials have a density placing them in the category of heavy metal:

- Mercury

- Lead

- Nickel

- Vanadium

- Zinc

IMO Annex VI regulation 16 prohibits incineration on ship of certain products, such as contaminated packaging materials and polychlorinated biphenyls (PCBs).

Criteria for selection of proper sized incinerator

When choosing an incinerator, several factors should be considered:

- The intention of the incinerator. Incineration of sludge oil, solid waste or both

- Requested capacity for burning of sludge oil. It is recommended to choose an incinerator with the capacity to burn approx. 1% of the ship’s daily bunker consumption, incinerated within 8-12 hours of operation. The equivalent sludge tank capacity should correspond to 2% of the daily bunker consumption

- Requested capacity for burning of solid waste. Estimated amount of solid waste onboard a vessel is approx. 2 kg per person, and for cruise liners approx. 3 kg per person.

Recommendations for installation of a marine incinerator system

An incinerator consists of a combustion chamber with burner unit, sludge burning equipment and an electric control panel. It is usually assembled in one complete unit resting on 4 or 6 feet or on pads. The unit is welded or bolted firmly to the deck, platform or the ground. Due to the working of the flue gas/cooling fan, always ensuring neccesary underpressure in the combustion chamber, there are no limitations to where the incinerator can be installed onboard the vessel. The flue gas is delivered as a separate unit, and is installed in the most convenient place close to the incinerator, or away from the unit itself. For instance in the funnel. Containerized units for installation on deck or for onshore facilities, can also be supplied.

Certificates

Incinerators are certified in compliance with IMO-Resolution MEPC. 244(66) adopted April 4th, 2014 (Replacing MEPC. 76(40)), Standard Specifications of Shipboard Incinerators, and IMO MARPOL ANNEX VI adopted 26. September 1997. Most incinerators have type approvals from DNV, USCG, ABS, LRS, GL and RMRS for most models, and will usually satisfy requirements of other classification societies.